Manifolds

Diesel Exhaust Manifolds | 5.9L & 6.7L Cummins, 4BT/3.9L, ISX15/X15

Precision-cast, crack-resistant diesel manifolds engineered for airflow, heat control, and long service life. Options for light-duty Cummins pickups and heavy-duty ISX/X15 platforms.

High-Flow Exhaust Manifolds Designed to Reduce Drive Pressure

Diesel Power Source manifolds are built to move heat and exhaust efficiently so your turbo can stay in its sweet spot. Thick-wall castings, reinforced partitions, and precision-machined flanges help reduce warping and leaks. Choose direct-fit stock-replacement or performance configurations (including T3, T4, and T4i) tailored to your engine and turbo setup.

Shop by platform

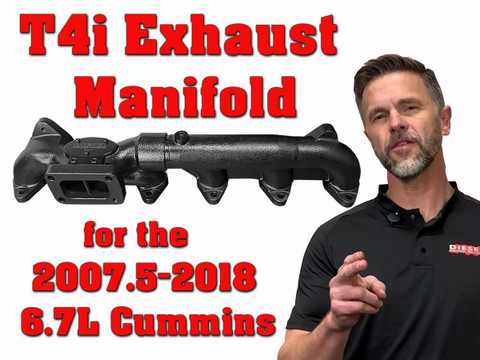

- 6.7L Cummins Manifolds – Stock-replacement and T4 options for 2007.5–2024 Ram.

- 5.9L Cummins Manifolds – 12V, 24V, and common-rail applications.

- ISX15/X15 Manifolds – Heavy-duty solutions for Class 8 routes.

- Cummins 4BT/3.9L Manifolds – Compact performance for swaps and industrial.

Why upgrade your diesel exhaust manifold

- Lower drive pressure & EGT: Smoother runners and efficient collectors reduce backpressure under load.

- Faster turbo response: Stable pulse energy helps the turbo light sooner and pull harder through midrange.

- Strength & durability: Thick-wall castings, robust partitions, and flat-machined flanges resist cracking and leaks.

- Service friendly: Pre-tapped ports (where noted) simplify EGT/pressure monitoring and diagnostics.

Construction that matters

- Precision casting & machining: Flat sealing surfaces for reliable gasket crush and bolt torque retention.

- Thermal management: Designs that tolerate continuous load, heat cycling, and towing duty.

- Correct flange geometry: T3/T4/T4i styles for common turbo inlets.

How to choose the right manifold

- Keep your stock turbo? Pick a direct-fit stock-replacement manifold for OEM flange and angle.

- Upgrading the turbo? A T4/T4i performance manifold provides headroom and stable boost control.

- Tow or run hot climates? Prioritize thicker castings and proven crack resistance with monitoring ports.

When to replace your manifold

- Ticking or hissing on cold start that fades warm (leak at gasket or crack).

- Visible cracks/soot marks near divider walls or flange edges.

- Higher EGT/lag after load with no other system changes.

- Warped flanges or recurring gasket failures.

Install & maintenance tips

- Use new gaskets and quality hardware; follow factory torque sequence in stages.

- Apply high-temp anti-seize to studs/nuts; re-torque after initial heat cycles if specified.

- Inspect turbo mounting face and downpipe alignment to prevent stress on joints.

- Pressure test charge-air system and check for upstream exhaust leaks after install.

Planning supporting upgrades? See 3rd Gen Swap Kits, Add-A-Turbo Kits, and Turbonator® VGT Upgrades.

Refine:

Manifolds - Frequently Asked Questions

Factory manifolds are built for cost and packaging, not performance. Upgrading to a performance exhaust manifold can reduce drive pressure, improve airflow to the turbo, lower exhaust gas temperatures, and support higher horsepower and torque.

Yes. Lower backpressure and steadier turbo operation can help manage heat and drivability with factory systems in place when installed as directed.

Most of our manifolds are designed as direct bolt-on replacements for the factory manifold. They use factory mounting locations and are intended to install without custom fabrication. Always check the product description for specific fitment details.

New gaskets are recommended. Replace stretched or corroded studs/nuts. Always follow the correct torque pattern.