Basic of Turbochargers

Posted by Diesel Power Source on Jan 27, 2025

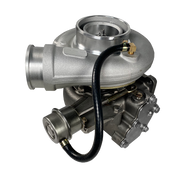

Why Turbochargers Are So Exciting, and the Basics of How They Work

As a teen, I really wanted to figure out how to make power in my own car. After working on naturally aspirated engines for years, I got tired of the compromise of either having something drive able or having something with a lot of power. Then along came pickups with diesel engines and turbochargers. By this time in my life I had received a Masters in Engineering Design, and combined what I now knew to start making advancements in this exciting field of turbo diesel engines. The exciting thing is that a turbo diesel can make a lot of power, be very fast, and have still be daily driven. This is largely because of the turbochargers used on today’s Ford, Cummins and Duramax diesels.

Here’s some of the basics to begin with.

A turbocharger is axial pump on the front on the compressor wheel. It is also a centrifugal pump on the back part of the compressor wheel.

If a compressor wheel is designed properly, it works great and is extremely efficient. It can push air in excess of a 4:1 ratio. A jet engine is an axial compressor and only compresses air in a 1.1-1.2:1 ratio, so a turbocharger it is much more effective in pressurizing the air through the compressor wheel.

Are you wondering why? It is because when a turbocharger compressor wheel is spinning, air enters the front of the turbo and passes through the centrifugal compressor and multiplies the air pressure ratio. Then, the air dissipates into the little snail shell we call a scroll or volute. As the air goes through the scroll, it slows down and becomes more pressurized and develops a higher density. It then exits the turbo charger then it enters into either the intercooler or engine.

On the exhaust side of things, a turbine wheel, which is usually made out of inconel, accepts the exhaust energy and causes it to spin which does two things: it takes the energy out of the exhaust in the form of pressure and also takes out energy in the form of heat. As a general rule, the air looses 10 degrees per pound of boost. So, if you are developing 30 PSI in a motor you are typically going to see exhaust temps drop by about 300 degrees after the turbine wheel. The turbine does convert some of the heat energy into energy that goes back in form of boosted air, so it is also a heat exchanger and some of the heat energy is reused, instead of just being wasted. This is one reason a turbo is more efficient than a supercharger.

The turbine wheel is actually part of the shaft, and the shaft is fastened to the compressor wheel. The shaft rotates in place by bearings, either journal and thrust bearing combination, or ball bearings which keep it from moving and side to side, front to back. In very simplistic terms, it is one fan connected to another fan. The one side spins by the exhaust and the other side spins and pushes air into the engine.

While the basic concept of a turbo is simple, the science in designing it to properly work, is extremely complex. Aside from the designing of turbochargers, there are many variables that determine how well turbocharges will work with your engine, so be sure you are buying the from the right place, from someone who isn’t just selling you a general turbo, that they’ve heard works well.